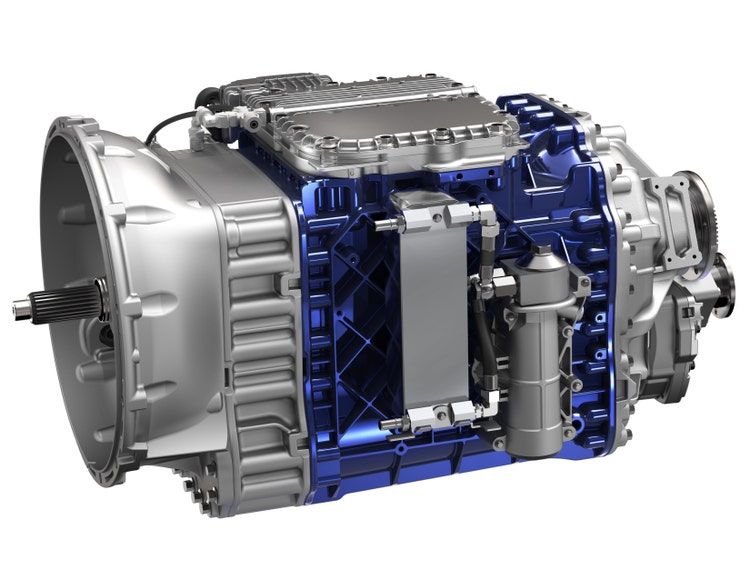

Volvo Trucks’ I-Shift Transmission Technology Still Leading Innovation in North America After 15 Years

Volvo Trucks’ revolutionary I-Shift intelligent automated manual transmission celebrates 15 years in North America in 2021, and continues to set industry benchmarks for fuel efficiency, vehicle performance, safety and driver comfort.

Originally introduced in Europe in 2001, more than 1 million Volvo trucks around the world have been sold with the Volvo I-Shift transmission, reinforcing Volvo Trucks’ belief in a clutch-based transmission system as the most efficient design for automated gear changing. The Volvo I-Shift made its game-changing North American debut in 2007, and by 2013 was a standard feature across the entire model range, resulting in a current overall order rate of 94%.

“More than 217,000 Volvo trucks have been sold with the Volvo I-Shift since its launch 15 years ago in North America, marking a significant change in a market where manual shifting was a very strong tradition,” said Johan Agebrand, director of product marketing at Volvo Trucks North America. “The Volvo I-Shift transmission is the result of many years of hard work and dedication by our engineers and represents significant technological advances across the global Volvo Trucks organization.”

The Volvo I-Shift uses intelligent electronics to continuously monitor grade, speed, weight and engine load, either shifting or holding a gear as needed to conserve fuel. The transmission system is fully synchronized and integrated with the rest of the truck, using information available from both the engine and the vehicle to optimize operations for different applications and tractor-trailer combinations. The Volvo I-Shift helps professional drivers operate more efficiently, regardless of experience or training. Besides keeping fuel costs down, it can also help slow driveline wear, extend transmission life, lower maintenance costs and increase vehicle uptime.

Being an automated system, the Volvo I-Shift not only increases fuel efficiency and reduces environmental impact, it also contributes significantly to improved driveability due to its exceptionally high responsiveness and seamless shifting capabilities. Less fatigue, fewer distractions and reduced stress improves safety, driver operations and physical health – benefits that serve to enhance driver recruitment, training, performance and retention.

For 15 years, Volvo Trucks North America has continued to pioneer numerous new intelligent functions that exemplify the industry-leading technology integrated within the Volvo I-Shift system, including:

Volvo I-Shift with Crawler Gears – When steep-grade startability and low-speed maneuverability are critical for maximum loads, the Crawler Gears option enables controlled forward and reverse travel at extremely slow speeds, offering the highest weight capacity in an automated manual transmission.

Volvo I-Shift for Severe Duty – Combining efficiency and durability, the 12-speed Volvo I-Shift for Severe Duty is designed for the most rigorous on/off-road work in construction and heavy-haul applications. Standard on Volvo VHD models, the Volvo I-Shift for Severe Duty features hardened gears and other hardware to help withstand frequent shifting in rugged operating environments.

Volvo I-See Predictive Cruise Control – This feature employs self-learning knowledge of road topography to recognize slopes and grades, and optimize the truck's approach speed, gear-shifting and braking in the most fuel-efficient way.

Today, further innovations from Volvo Trucks has made the industry's most advanced automated manual transmission even better. The latest edition of the Volvo I-Shift includes upgraded hardware and software, greater durability and a new countershaft brake for improved performance and smoother shifting. The electronic control unit can handle a wide variety of loads and terrains, shifting accurately and evenly.

Additionally, the Volvo I-Shift transmission has the capability of over-the-air programming, enabling easy customizations of transmission software and shift logic to accommodate changes in application, duty cycles, terrain and driver preference. By using Volvo Trucks’ Remote Programming services, software updates are done within minutes rather than visiting a workshop and taking the truck out of service, greatly increasing uptime.

“Volvo Trucks revolutionized the North American trucking industry when it introduced the Volvo I-Shift transmission to the market 15 years ago,” Agebrand added. “It’s one more example of how Volvo Trucks has changed the face of the transport industry in the U.S. and Canada and continues to do so today.”

CAPTION: Volvo Trucks North America’s revolutionary I-Shift automated manual transmission has set new standards in safety, sustainability and performance in the transport industry in the U.S. and Canada over the past 15 years.

Download Press Release Images